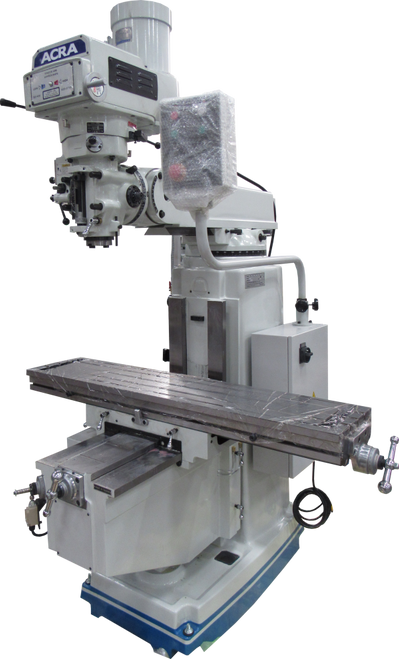

Experience the power and precision of the Knuth Servomill UWF 5 - a revolutionary servo-conventional knee and column milling machine that combines the familiar feel of a manual mill with the advanced capabilities of a CNC. This versatile machine from Omni Machine Inc. delivers unparalleled rigidity, accuracy, and efficiency for a wide range of milling applications.

The Servomill UWF 5 features an extremely rigid cast iron body with heavy ribbing and hardened, precision-ground ways for superior vibration dampening and long-term accuracy. Its powerful 10HP horizontal spindle, supported by a heavy-duty top beam and outer arbor, ensures exceptional performance even when using long cutter arbors. Precision-ground and hardened spindle gears run smooth and quiet.

This advanced mill utilizes servo-conventional drives on all axes, providing infinitely variable feed rates and rapid traverse speeds up to 197 IPM. Preloaded ball screws increase precision while reducing backlash and wear. Electronic handwheels offer the familiar feel of manual operation with enhanced control.

Features:

- Robust Meehanite cast iron construction with heavy ribbing

- Precision-ground and hardened ways for accuracy and wear resistance

- 10HP high-torque horizontal spindle with outer arbor support

- Hardened and ground spindle gears for quiet, durable operation

- Servo-conventional drives with infinitely variable feed rates

- Rapid traverse up to 197 IPM for increased productivity

- Preloaded ball screws on all axes reduce backlash

- Electronic handwheels for precise manual control

- Electronic fixed stops increase setup efficiency

- Swiveling milling head with 360° rotation capability

Specifications:

Working Area:

- Table: 63" x 13"

- Table Load: 660 lbs

- 3 T-slots (0.7" width, 3.1" spacing)

Travels:

- X-Axis: 51.2"

- Y-Axis: 11"

- Z-Axis: 18"

Spindle:

- Speeds: 60-1800 RPM (2 Ranges)

- Taper: ISO 50

- Swivel: 360°

- Center to Table: 8-23"

Feeds:

- X/Y/Z Cutting: 0-39 IPM

- X/Y/Z Rapid: Up to 197/118/59 IPM

Motor:

- 10.1 HP Main Drive

Size/Weight:

- Dimensions: 99" x 83" x 79"

- Weight: 6,160 lbs

Equipped With:

- 3-Axis Position Indicator

- Electronic Handwheels

- ISO 50 Reducing Sleeve, Milling Arbors

- ISO 50 Collet Chuck (8 Collets)

- Coolant System

- Work Lamp

- Chip Tray

- Foundation Bolts

- Tools and Manual