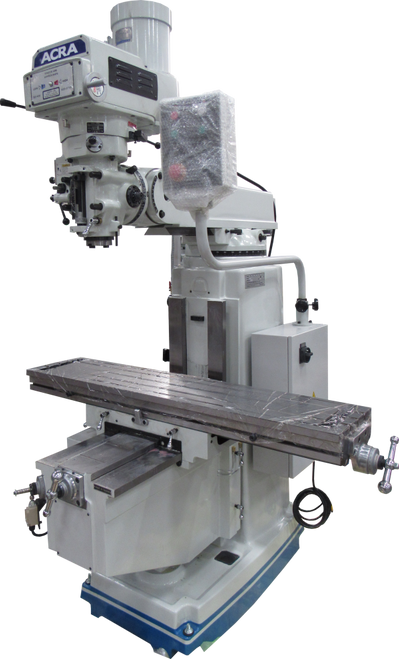

Product Overview

Introducing the Acra LC-25VH Vertical & Horizontal Variable Speed Milling Machine, a top-of-the-line machine designed for unparalleled accuracy, longevity, and durability. This state-of-the-art milling machine, available from Omni Machine Inc. and other trusted distributors, delivers exceptional performance and versatility for a wide range of milling applications. With its robust construction, advanced features, and user-friendly design, the Acra LC-25VH is the ideal choice for workshops, manufacturing facilities, and industrial settings demanding the highest levels of precision and reliability.

The Acra LC-25VH Vertical & Horizontal Variable Speed Milling Machine is a testament to superior engineering and craftsmanship. Built with genuine Meehanite castings, this machine offers unparalleled stability and vibration damping, ensuring consistent accuracy and smooth operation. The hardened and ground box knee ways, combined with the box column ways and double box-type Turcite-coated saddle ways, provide exceptional rigidity and precision, even under heavy loads.

The LC-25VH features double table and knee locks, ensuring secure workpiece holding and eliminating unwanted movement during cutting operations. The spring-loaded hand wheels enhance operator safety, while the precision hardened and ground table provides a stable and accurate work surface. The conveniently positioned control pendant puts all controls within easy reach, streamlining machine operation and increasing productivity.

With a generous 10″ x 56″ table size and extensive travel capabilities in the X, Y, and Z axes, the Acra LC-25VH accommodates a wide range of workpiece sizes and shapes. The 5″ quill travel, 18-1/2″ ram travel, and 17-1/2″ knee travel offer ample capacity for various milling tasks. The machine's versatile throat distance and spindle-to-table height range provide flexibility for diverse setups and applications.

The LC-25VH boasts both vertical and horizontal milling capabilities, with an NT No. 40 taper spindle in the vertical orientation and a robust horizontal spindle. The variable speed vertical spindle (60 – 4,500 RPM) and six-speed horizontal spindle (80 – 1,350 RPM) allow operators to optimize cutting parameters for different materials and tools. The precision quill feed rates (0.0016″, 0.003″, 0.006″ IPR) enable fine control and superior surface finishes.

The machine's head tilts 90° right-left and 45° up-down, providing additional flexibility for angled and compound milling operations. Powered by a 5 HP, 230 or 460V, 3 Phase, 60 Hz motor for both vertical and horizontal spindles, the Acra LC-25VH delivers ample cutting power and performance for demanding milling applications.

Features:

- Genuine Meehanite castings for superior stability and vibration damping

- Hardened and ground box knee ways for rigidity and precision

- Box column ways and double box-type Turcite-coated saddle ways for accuracy and smooth operation

- Double table and knee locks for secure workpiece holding and elimination of unwanted movement

- Spring-loaded hand wheels for enhanced operator safety

- Precision hardened and ground table for a stable and accurate work surface

- Conveniently positioned control pendant for streamlined machine operation and increased productivity

- Generous table size and extensive travel capabilities in X, Y, and Z axes for accommodating diverse workpieces

- Vertical and horizontal milling capabilities with NT No. 40 taper vertical spindle and robust horizontal spindle

- Variable speed vertical spindle (60 – 4,500 RPM) and six-speed horizontal spindle (80 – 1,350 RPM) for optimizing cutting parameters

- Precision quill feed rates (0.0016″, 0.003″, 0.006″ IPR) for fine control and superior surface finishes

- Head tilt of 90° right-left and 45° up-down for angled and compound milling operations

- Powerful 5 HP, 230 or 460V, 3 Phase, 60 Hz motors for both vertical and horizontal spindles

Specifications:

- Table Size: 10″ x 56″

- X Axis Travel: 36″

- Y Axis Travel: 16-1/2″

- Z Axis Travel (Quill): 5″

- Ram Travel: 18-1/2″

- Knee Travel: 17-1/2″

- Throat Distance: 12-13/16″ ~ 30-11/16″

- Spindle Gauge Line to Table Top: 5-5/16″ ~ 23″

- Vertical Spindle Taper: NT No. 40

- Vertical Speed (Variable Speed): 60 – 4,500 RPM

- Quill Feed (IPR): 0.0016", 0.003", 0.006"

- Horizontal Speed (6 Speeds): 80 – 1,350 RPM

- Horizontal Spindle Center to Table: 0″ ~ 17-3/8″

- Horizontal Spindle Center to Overarm: 5-1/2″

- Horizontal Spindle Nose to Table: 5-5/16″~ 23″

- Head Tilt (right-left): 90°

- Head Tilt (up-down): 45°

- Vertical Motor: 5 HP, 230 or 460V, 3 Phase, 60 Hz

- Horizontal Motor: 5 HP, 230 or 460V, 3 Phase, 60 Hz

Equipped With:

- Flood Coolant System with Splash Pan for efficient chip removal and tool lubrication

- Longitudinal Power Feed with Rapid Traverse for fast and accurate table positioning

- Rapid Knee Traverse for quick and easy knee positioning

- Rear Rubber Way Cover for protecting ways from debris and ensuring smooth operation

- 1″ Diameter Horizontal Arbor for supporting horizontal milling tools

- Two Overarm Supports for increased rigidity during horizontal milling operations

- One-Shot Lubrication System for convenient and efficient machine lubrication

- Dual Cooling Fans for optimal temperature control and machine performance

- Emergency Stop for enhanced operator safety

- Tool Box for convenient storage of tools and accessories