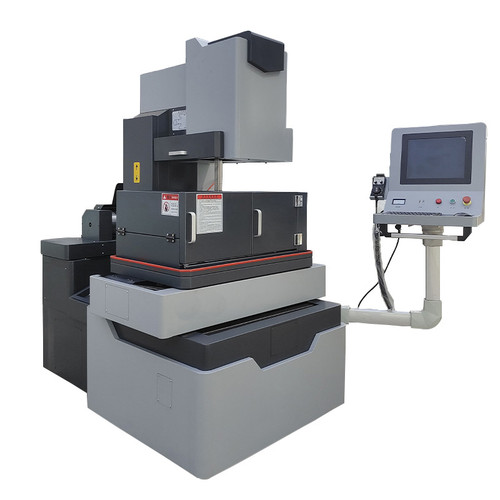

Product Overview

Introducing the OMBECOP Combined Drilling and Oxy-Fuel Cutting Machine Series from Omni Machine Inc. - a versatile and powerful solution for metal fabrication shops requiring both drilling and cutting capabilities in one comprehensive system. This state-of-the-art machine series combines advanced drilling technology with oxy-fuel cutting, offering unparalleled flexibility and efficiency in plate processing across a wide range of sizes.

The OMBECOP series features a robust design capable of handling plates of various dimensions, from compact to large-scale industrial applications. With its powerful 29.5 HP spindle and advanced Mitsubishi M700V CNC system, this machine delivers precise drilling and cutting operations for a wide range of applications in the metal fabrication industry.

Key Features:

- Combined drilling and oxy-fuel cutting capabilities in one system

- Available in a wide range of table sizes to suit various production needs

- Advanced Mitsubishi M700V CNC control system for intuitive programming and operation

- Powerful 29.5 HP spindle with speeds up to 3,000 RPM

- BT40 tool holder for versatile tool compatibility

- Oxy-fuel cutting capability up to 4" thickness

- High-speed plate positioning with 49 ft/min driving speed

- Protective barrier system for enhanced operator safety

- Integrated fume extraction unit for improved work environment

- Air cooling system for optimal performance

Technical Specifications:

- Plate thickness (Oxy Cutting): ⅓" - 4'

- Maximum plate positioning weight: 16,535 lbs

- Plate driving speed: 49 ft/min

- Drill unit holder: BT40

- Carbide drill diameter range: 0.4" - 1.5"

- U-drill diameter range: 0.4" - 2"

- Thread tapping capacity: M12 - M24

- Spindle power: 29.5 HP

- Spindle speed range: 100 - 3,000 RPM

Standard Features:

- Automatic Tool Changer (ATC)

- Chip conveyor

- Small parts lifting conveyor

- Hydro motorized chip cleaning brush

- Driving group linear car central lubrication system

- Hydraulic parts holding jaws (100mm)

- Oxy-head

- Hypertherm XPR300 plasma system

- Filter unit

Optional Features:

- Tool & material measurement system

- Hypertherm HPR400 plasma system upgrade

- Scribe marking with air (20,000 RPM)

- Scribe marking (3,000 RPM)

- Starter drill pack

- Bevel cutting capability

- Lantek bevel software

- Remotely operated device for service support (AUG)