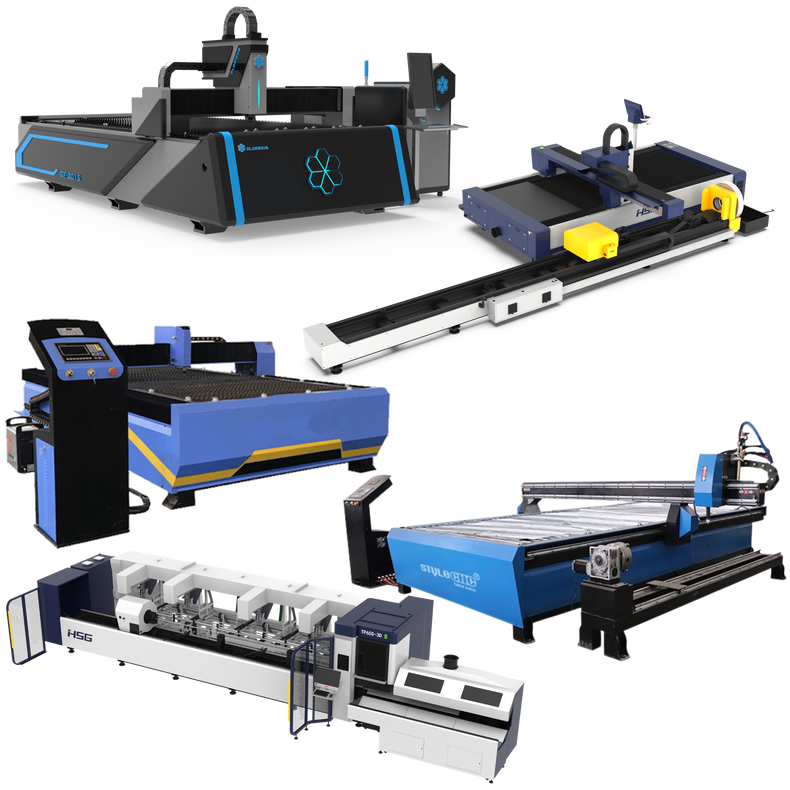

Laser cutting technology has revolutionized the manufacturing industry with its precision, speed, and efficiency. Two of the most popular types of laser cutting machines are CO2 and fiber laser cutting machines. In this blog, we will explore the differences and advantages of CO2 and fiber laser cutting machines and also include tube fiber laser machines.

CO2 Laser Cutting Machines:

CO2 laser cutting machines use a gas mixture of carbon dioxide, nitrogen, and helium to create a laser beam. The beam is directed through a series of mirrors and lenses to the cutting head, where it is focused into a small point to cut through the material. CO2 lasers are best suited for cutting non-metallic materials such as plastics, wood, and acrylic.

Advantages of CO2 Laser Cutting Machines:

Cost-Effective:

CO2 laser cutting machines are generally less expensive than fiber laser cutting machines, making them a more cost-effective option for businesses on a budget.

Versatility:

CO2 lasers can cut through a wide range of materials, including plastics, wood, and acrylic.

Higher Cutting Quality:

CO2 lasers produce a smoother cut edge and can achieve higher levels of detail than fiber lasers.

Reduced Maintenance: CO2 lasers require less maintenance than fiber lasers, making them a more user-friendly option.

Fiber Laser Cutting Machines:

Fiber laser cutting machines use a solid-state laser to create a laser beam. The laser beam is generated by pumping diodes with electrical energy, which excites the rare earth elements in the laser medium. The laser beam is then directed through fiber-optic cables to the cutting head, where it is focused into a small point to cut through the material. Fiber lasers are best suited for cutting metals such as steel, aluminum, and brass.

Advantages of Fiber Laser Cutting Machines:

Speed:

Fiber laser cutting machines are much faster than CO2 lasers, making them an ideal choice for high-volume production runs.

Higher Power:

Fiber lasers can generate higher power levels than CO2 lasers, allowing them to cut through thicker materials.

Greater Precision:

Fiber lasers are more precise than CO2 lasers, producing a narrower cut width and a smaller heat-affected zone.

Lower Operating Costs:

Fiber lasers require less energy to operate than CO2 lasers, resulting in lower operating costs over time.

Which is Right for Your Business?

When choosing between a CO2 or fiber laser cutting machine, it is essential to consider the types of materials you will be cutting, the volume of production, and your budget. If you primarily cut non-metallic materials and have a limited budget, a CO2 laser cutting machine may be the best option. However, if you work with metals and require high-volume production runs, a fiber laser cutting machine may be the better choice.

Conclusion:

CO2 and fiber laser cutting machines both offer advantages depending on your business needs. CO2 lasers are best suited for cutting non-metallic materials and offer cost-effectiveness, versatility, higher cutting quality, and reduced maintenance. Fiber lasers are best suited for cutting metals and offer speed, higher power, greater precision, and lower operating costs. When choosing between the two, consider your business needs and budget to make an informed decision.

Tube Lasers:

Now we will explore the basics of fiber tube lasers, their advantages, and their applications. Fiber tube lasers have become increasingly popular in recent years due to their superior performance and versatility. These lasers are a type of fiber laser that utilize a tubular optical fiber to amplify and transmit the laser beam.

What is a fiber tube laser?

A fiber tube laser is a type of fiber laser that utilizes a tubular optical fiber to amplify and transmit the laser beam. The tubular fiber is doped with rare-earth ions, typically erbium or ytterbium, which provide the laser gain.

The laser cavity of a fiber tube laser consists of a pump diode, the doped tubular fiber, and two mirrors that reflect the laser beam back and forth through the fiber. The pump diode provides the energy to excite the rare-earth ions, which then emit photons that are amplified as they pass through the fiber.

Advantages of fiber tube lasers:

Fiber tube lasers offer several advantages over traditional solid-state lasers:

Higher power:

Fiber tube lasers can produce much higher output power than solid-state lasers due to their ability to scale the active fiber diameter.

Better beam quality:

The tubular geometry of the fiber provides a more stable and symmetric mode profile, resulting in better beam quality and higher brightness.

Longer lifetime:

The optical fiber is a passive component that does not degrade over time, unlike solid-state laser crystals that can suffer from thermal damage and other degradation mechanisms.

Flexible wavelength:

The rare-earth dopants used in the fiber can be chosen to provide laser emission at a wide range of wavelengths, from the near-infrared to the mid-infrared.

Applications of fiber tube lasers:

Fiber tube lasers have a wide range of applications in industrial, scientific, and medical fields. Some examples include:

Material processing:

Fiber tube lasers are used for cutting, welding, drilling, and surface treatment of metals, ceramics, and polymers.

Medical applications:

Fiber tube lasers are used in medical applications such as ophthalmology, dentistry, and dermatology for procedures such as laser eye surgery, dental treatments, and skin resurfacing.

Scientific research:

Fiber tube lasers are used in scientific research for spectroscopy, metrology, and nonlinear optics.

Defense and security:

Fiber tube lasers are used in defense and security applications such as remote sensing, laser weapons, and laser communications.

Conclusion:

Fiber tube lasers offer several advantages over traditional solid-state lasers, including higher power, better beam quality, longer lifetime, and flexible wavelength. They have a wide range of applications in industrial, scientific, and medical fields, and their versatility and performance make them an attractive option for many laser applications.