Product Overview

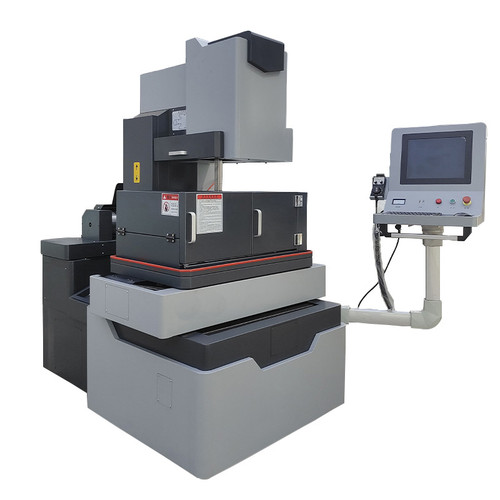

Introducing the Acra CNC Wire Cut EDM (Electric Discharge Machine), a state-of-the-art machining solution designed for high-precision cutting of low conductivity materials such as PCD and CBN. With its advanced features, robust construction, and user-friendly interface, this wire EDM machine delivers exceptional accuracy, efficiency, and versatility, making it an ideal choice for manufacturers seeking to optimize their machining processes and achieve superior results.

The Acra CNC Wire Cut EDM is a cutting-edge machine that combines precision engineering, innovative design, and advanced technology to provide unparalleled performance in machining low conductivity materials. The machine features a functional U & V axis design, with the axes strategically placed on the upper column to enhance precision taper cutting. The rigid and symmetrical machine base, constructed from properly aged and annealed high-quality Meehanite cast iron, ensures minimal deflection under load. The precision ballscrews of C1 type and linear motion guide ways on the X, Y, Z, U, and V axes, coupled with direct drive A/C servo motors, eliminate backlash and enable accurate positioning. The stainless steel slide-type work table and high-efficiency fluid supply system further contribute to the machine's outstanding performance. The industrial CNC controller offers a user-friendly interface with features such as easy data input, symbolic graphic display, auto wire threading, NC programming, and photo graph preview function, making operation and programming a breeze.

Features:

- Functional U & V axis design for enhanced precision taper cutting

- Rigid and symmetrical machine base made from high-quality Meehanite cast iron

- Precision ballscrews and linear motion guide ways on X, Y, Z, U, and V axes

- Direct drive A/C servo motors for accurate positioning and backlash elimination

- Stainless steel slide-type work table for durability and precision

- High-efficiency fluid supply system for optimal machining performance

- User-friendly industrial CNC controller with advanced features and functions

- Versatile cutting capabilities for various materials, including PCD, CBN, tungsten carbide, and more

Specifications:

- Maximum Table Size: 25" x 19"

- Maximum Work Piece Size: 29" x 20" x 11"

- Maximum Work Piece Weight: 1,100 Lbs.

- X/Y Axis Travels: 15" x 11"

- U/V Axis Travels: 3.9" x 3.9"

- Z Axis Travel: 11"

- Wire Diameter: 0.1 ~ 0.3 mm

- Maximum Taper Angle & Thickness: ±15° / 3.3"

- Water Tank Capacity: 71 Gallons

- Maximum Cutting Speed: <200mm²/min

- Maximum Stable Cutting Speed: 160mm²/min (Work piece Material: SKD11)

- Conductivity: Automatic

- Maximum Wire Bobbin Weight: 13 Lbs.

- Surface Roughness: Ra 0.30 μm

- Machining Accuracy: ±3 μm (Thickness: 20 mm)

Installation Requirements:

- Input Voltage: A/C local Voltage =-10% ~ 3 Phase, 60 HZ

- Power Consumption: 15 KVA (Without Water Chiller)/ 18 KVA (With Water Chiller), Temperature Range (5 ~ 25°C)

- Environment: Temperature (20°C Dust Free), Humidity (Under 75% RH), Vibration (Under 0.6mm/S2)

- Ground: Machine has to be grounded to avoid abnormal interference of voltage.

Standard Accessories:

- 1 Set - Wire Guide ø 0.25 mm (upper & lower)

- 1 Roll - Brass Wire ø 0.25 mm / 5 kg / roll

- 1 Set - Water system (Excluding water chiller)

- 1 Set - Remote control box

- 1 Set - Tool box

- 1 Set - Filter (2 pcs/set)

- 1 PC - Ion exchange resin (5 L)

- 1 Set - Water nozzle (upper & lower)

- 1 Set - Automatic vertical alignment jig

- 1 Set - Power feed contact (2 pcs/set)

- 1 Set - Clamping tools