Product Overview

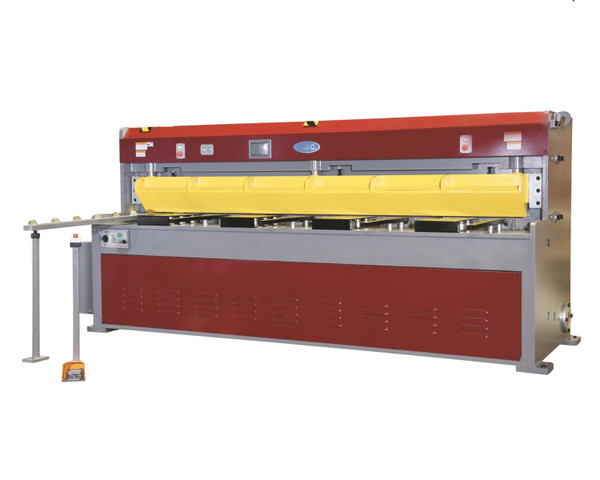

Introducing the GMC Heavy Duty Hydraulic Shear, a state-of-the-art shearing solution manufactured in Taiwan to deliver unparalleled performance and precision. Designed for demanding industrial applications, this hydraulic shear boasts an impressive array of features, including a 36" NC touch screen front-operated power back gauge with micro adjustment and inch/metric digital display, automatic quick change blade gap adjustment, and a CE-standard "OMERO" electric control system. With its robust construction and advanced hydraulic technology, the GMC Heavy Duty Hydraulic Shear is the ultimate tool for efficient and accurate cutting of various materials.

The GMC Heavy Duty Hydraulic Shear is a cutting-edge machine that combines power, precision, and user-friendly features to streamline your cutting operations. This ISO 9001 certified shear is designed to meet stringent OSHA safety standards and features a shadow line for accurate straight cutting operations. The adjustable cutting length and stroke, coupled with the ball transfer plates on the worktable, ensure smooth and effortless loading of workpieces. The well-balanced and sturdy all-steel machine frame provides exceptional stability, while the German-made hydraulic system operates quietly and efficiently from a central location. The hydraulic hold-downs feature anti-mark neoprene to protect your material's surface, and the high-grade carbon/chrome alloy steel shear blades, hardened to 60 HRC, guarantee clean and precise cuts. With 2-edge indexable upper blades and 4-edge indexable bottom blades, this shear offers extended blade life and minimal maintenance. The full-length, viewable safety finger guard protects operators from cutting hazards, while the hydraulic system's overload protection ensures long-lasting performance. The compact operator control panel and multiple cutting modes, including jog and continuous auto cycle, provide flexibility and ease of use.

Features:

- 36" NC touch screen front-operated power back gauge with 0.004" micro adjustment and inch/metric digital display

- ISO 9001 certified for quality assurance and consistency

- Automatic quick change blade gap adjustment with convenient dials

- CE-standard "OMERO" electric control system for reliable performance

- Compliant with OSHA safety standards for operator protection

- Shadow line for accurate straight cutting operations

- Adjustable cutting length and stroke for versatile applications

- Ball transfer plates on worktable for smooth and easy workpiece loading

- Robust all-steel machine frame for exceptional stability and durability

- Quiet and centrally located German-made hydraulic system for optimal performance

- Hydraulic hold-downs with anti-mark neoprene to protect material surfaces

- High-grade carbon/chrome alloy steel shear blades hardened to 60 HRC for clean, precise cuts

- 2-edge indexable upper blades and 4-edge indexable bottom blades for extended blade life

- Full-length, viewable safety finger guard to protect operators from cutting hazards

- Hydraulic system overload protection for long-lasting performance

- Compact operator control panel for ease of use

- Versatile cutting modes, including jog and continuous auto cycle, for flexibility

Specifications:

- Capacity (Overall): 1/4" x 10'

- Mild Steel Capacity: 1/4"

- Stainless Steel Capacity: 3/16"

- Maximum Cutting Length: 120"

- Blade Length: 10'

- Strokes per Minute: 10-12

- Throat Depth: 18"

- Worktable Height: 34-1/2"

- Blade Rake Angle: 2°

- Front Support Arm Length: 24"

- Back Gauge: 24" (NC Power)

- Oil Tank Capacity: 30 Gallons

- Backgauge Motor (Servo): 1 HP

- Main Motor: 15 HP

- Voltage: 220V, 3 Phase

Equipped With:

- 36" NC touch screen front-operated power backgauge for precise positioning

- 60" squaring arm with convenient dual-scale inch/metric measurement

- Removable safety foot pedal for hands-free operation

- Two 24" front support arms for material handling and support

- Material support and drop back chufer for efficient material handling