Product Overview

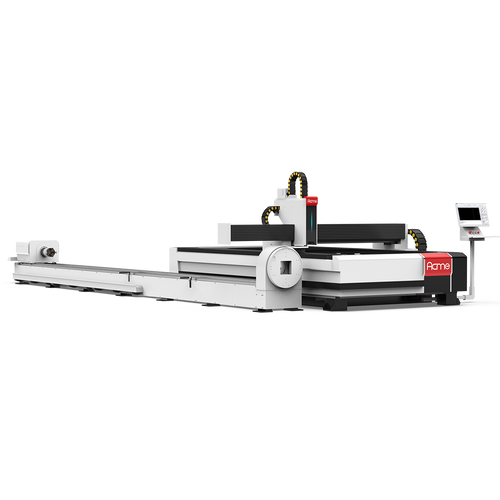

Introducing the LP-3015S Single Table Fiber Laser Cutting Machine from Omni Machine Inc. - a revolutionary solution for high-precision, efficient cutting of metal sheets. This state-of-the-art laser cutting system combines advanced fiber laser technology, a robust mechanical design, and user-friendly software to deliver unparalleled performance and flexibility. With its spacious working area, powerful laser source options, and extensive features, the LP-3015S is the perfect choice for businesses seeking to optimize their metal cutting processes and achieve exceptional results.

Omni Machine Inc.'s LP-3015S Single Table Fiber Laser Cutting Machine is a top-of-the-line system designed to streamline metal cutting operations. Built upon a sturdy, welded steel frame, this machine ensures superior stability and long-lasting performance. The high-powered fiber laser source, available in various wattages up to 6 kW, enables fast, precise cutting of a wide range of materials and thicknesses. The LP-3015S features a user-friendly CypCut 2000C control system, which offers intuitive programming and seamless integration with CAD/CAM software. The spacious 120 x 60 inch (3000 x 1500 mm) working area accommodates large sheets, while the high-speed servo motors and linear guide rails ensure accurate, smooth motion. The machine is equipped with a range of advanced features, including an auto-focus cutting head, capacitive height sensor, and efficient fume extraction system, to optimize cutting quality and performance.

Features:

- High-powered fiber laser source with options up to 6 kW for fast, precise cutting

- Spacious 120 x 60 inch (3000 x 1500 mm) working area for accommodating large sheets

- Sturdy, welded steel frame construction for superior stability and durability

- User-friendly CypCut 2000C control system with intuitive programming and CAD/CAM compatibility

- High-speed servo motors and linear guide rails for accurate, smooth motion

- Auto-focus cutting head with capacitive height sensor for consistent cutting quality

- Efficient fume extraction system for improved air quality and component protection

- Automatic lubrication system for reduced maintenance and extended component life

- Compact, ergonomic design for easy integration into various workshop environments

Specifications:

- Working Area: 120 x 60 inches (3000 x 1500 mm)

- Laser Power: 1,000 W - 6,000 W

- Max. Positioning Speed: 4,720 inches/min (120 m/min)

- Positioning Accuracy: ±0.001 inch (±0.03 mm)

- Repeatability: ±0.0004 inch (±0.01 mm)

- Max. Acceleration: 1.5 G

- Max. Material Thickness (Mild Steel): 1.18 inch (30 mm) with 6 kW laser source

- Control System: CypCut 2000C

- Servo Motors: Yaskawa

- Guide Rails: HIWIN linear guide rails

- Dimensions (L×W×H): 236 x 110 x 71 inches (6000 x 2800 x 1800 mm)

- Weight: 11,000 lbs (5,000 kg)

Equipped With:

- High-powered IPG/MAX/Raycus fiber laser source (1,000 W - 6,000 W)

- Raytools BM110 (1-3 kW) / Raytools BM06K (4-6 kW) auto-focus cutting head

- Hanli water chiller for laser source cooling

- CypCut 2000C control system with user-friendly interface

- Yaskawa servo motors for high-speed, accurate motion

- HIWIN linear guide rails for smooth, precise movement

- Schneider Electric electrical components for reliable operation

- SMC pneumatic components for consistent performance

- Efficient fume extraction system with air filtration

- Automatic lubrication system for reduced maintenance

Available Options:

- Fiber laser source power upgrades (up to 6 kW)

- Raytools cutting head upgrades for enhanced performance

- CypCut nesting software for efficient material utilization

- Automated sheet loading/unloading systems for increased productivity

- Fume extraction and air filtration upgrades for improved air quality

- Customized working area dimensions to suit specific requirements

- Extended warranty and preventative maintenance plans for peace of mind