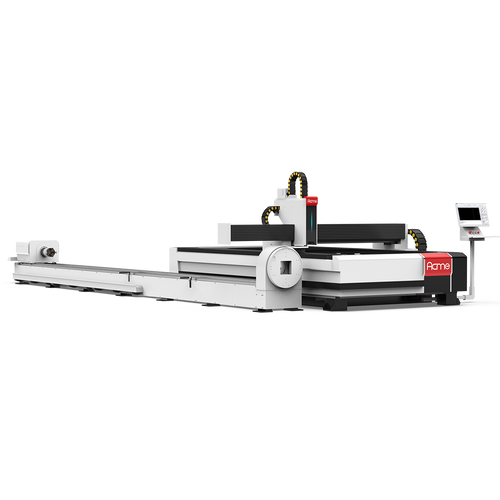

Introducing the LT-12038TK Heavy Duty Bevel Cutting Metal Tube Fiber Laser Cutting Machine from Omni Machine Inc. - an innovative solution for high-precision, efficient cutting and bevel processing of metal tubes and profiles. This cutting-edge laser cutting system combines robust mechanical design, advanced fiber laser technology, and intelligent software to deliver unmatched performance and versatility. With its extensive cutting capabilities, user-friendly interface, and powerful features, the LT-12038TK is the ultimate choice for industries demanding superior quality and productivity in heavy-duty tube and profile cutting applications.

Omni Machine Inc.'s LT-12038TK Heavy Duty Bevel Cutting Metal Tube Fiber Laser Cutting Machine is a top-tier system designed to revolutionize tube and profile cutting processes. Engineered with a rugged, side-mounted machine bed, this cutting machine ensures exceptional stability and precision. The state-of-the-art fiber laser source, available in power options up to 12 kW, enables rapid, accurate cutting of a wide range of materials and thicknesses. The machine boasts advanced CNC controls, powered by the FSCUT 5000A Ethercat system, which offers intuitive programming and seamless integration with CAD/CAM software. The three-chuck design, with pneumatic clamping and servo-driven support, accommodates tubes and profiles up to 14.96 inches (380 mm) in diameter and 39.4 feet (12 meters) in length, while the adjustable pneumatic wheel support system ensures stable material handling throughout the cutting process. Equipped with bevel cutting capabilities, the LT-12038TK can efficiently process angles up to ±45°, expanding its application range and enabling the creation of complex, ready-to-assemble components.

Features:

- Heavy-duty, side-mounted machine bed for exceptional stability and precision

- State-of-the-art fiber laser source with power options up to 12 kW for fast, accurate cutting

- Advanced FSCUT 5000A Ethercat CNC control system for intuitive programming and seamless CAD/CAM integration

- Innovative FSCUT TubePro 3D cutting software and TubesT 3D nesting software for efficient job setup and optimization

- Three-chuck design with pneumatic clamping for secure material holding and support

- Servo-driven floating support system with 14 supports for stable material handling during cutting

- Extensive cutting capabilities for tubes and profiles up to 14.96 inches (380 mm) in diameter and 39.4 feet (12 meters) in length

- Bevel cutting capabilities up to ±45° for processing complex, ready-to-assemble components

- High-performance motion control components, including servomotors, linear guides, and helical racks, for accurate and smooth operation

- Efficient fume extraction system and automatic lubrication for enhanced performance and maintenance

Specifications:

- Laser Power: 1,000 W - 12,000 W

- Maximum Tube/Profile Diameter: 14.96 inches (380 mm)

- Maximum Tube/Profile Length: 39.4 feet (12,000 mm)

- Bevel Cutting Range: ±45°

- Maximum Positioning Speed: 4,720 inches/min (120 m/min)

- Positioning Accuracy: ±0.004 inches (±0.1 mm)

- Repeatability: ±0.002 inches (±0.05 mm)

- Laser Source: MAX Photonics

- CNC Control System: FSCUT 5000A Ethercat

- Servomotors & Drivers: Innovance

- Linear Guides: HIWIN

- Helical Racks: YYC

- Dimensions (L×W×H): 787 x 138 x 138 inches (20,000 x 3,500 x 3,500 mm)

- Weight: 33,070 lbs (15,000 kg)

Equipped With:

- Boci BLT642H (1-12 kW) auto-focus laser cutting head

- FSCUT TubePro 3D cutting software and TubesT 3D nesting software

- Hanli water chiller for laser source cooling

- 14 servo-driven floating supports for stable material handling

- Three-chuck design with pneumatic clamping for secure material holding

- Innovance servomotors and drivers for precise motion control

- HIWIN linear guides and YYC helical racks for accurate and smooth operation

- Schneider Electric electrical components for reliable performance

- SMC pneumatic components for consistent operation

- Efficient fume extraction system with air filtration

- Automatic central lubrication system for reduced maintenance

Available Options:

- Fiber laser source power upgrades (up to 12 kW)

- Boci laser cutting head upgrades for enhanced performance

- Servo-driven floating support extensions for longer materials

- Tube and profile loading and unloading automation solutions for increased efficiency

- Dust collector and air compressor for optimal performance

- Customized chuck sizes and configurations for specific applications

- Extended warranty and preventative maintenance plans