Product Overview

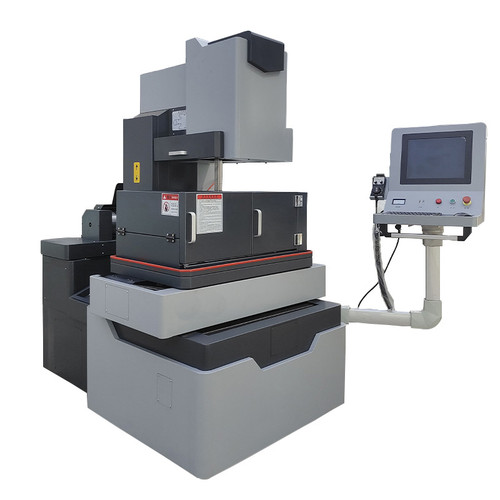

Revolutionize your manufacturing efficiency with the Shinzawa MTS-500 twin spindle vertical machining center. This innovative dual-spindle design allows for simultaneous machining of two parts, effectively doubling your output while significantly reducing floor space requirements. With high-speed 10,000 RPM spindles and independent tool magazines for each spindle, the MTS-500 is the perfect solution for high-volume production applications.

The Shinzawa MTS-500 twin spindle VMC is engineered to maximize throughput and minimize per-part costs in demanding manufacturing environments. By utilizing two spindles working in unison, this machine drastically cuts cycle times compared to single-spindle machining centers. The rugged construction, high-speed spindles, and advanced features make it an ideal choice for automotive, aerospace, medical, and other industries requiring efficient mass production of precision components.

Key Features:

- Patented dual-spindle design enables simultaneous machining for unmatched productivity

- Independent 10,000 RPM direct-drive spindles deliver powerful cutting performance

- Separate 24-tool magazine for each spindle minimizes non-cutting tool change time

- Ultra-wide column and spindle head span ensures superior stability and precision

- Roller-type linear guideways on all axes provide vibration-free high-speed motion

- Rigid cast iron base with V-shaped ribbed design for optimal static and dynamic stiffness

- Real-time process monitoring with intuitive dual-screen interface for maximum control

- Compatible with a range of high-productivity optional accessories and automations

Specifications:

- X/Y/Z Axis Travel: 19.7" x 23.6" x 22.4" (500 x 600 x 570 mm)

- Table Size: 59.1" x 23.6" (1500 x 600 mm)

- Maximum Table Load: 1,543 lbs (700 kg)

- Spindle Speed: 10,000 RPM

- Spindle Power: 7.5 / 11 kW

- Rapid Traverse Rate: 98.4 ipm (36 m/min)

- Tool Magazine Capacity: 24 tools (30 optional)

- Machine Weight: 18,519 lbs (8,400 kg)

Standard Equipment:

- Mitsubishi M730VW control with RS232 interface, MPG handwheel, and CF card

- Rigid tapping function

- Auto power off M30

- Dual internal spindle coolant, air blast, and oil cooling systems

- Automatic part probe and tool breakage detection

- Spindle air blast nozzles

- Full enclosure with splash guards

- Dual arm-type automatic tool changers

- Automatic lubrication system with low lubrication alarm

- LED work light

- Coolant flush gun and air gun

- Lift-up chip conveyor with chip cart

- Tool box and machine leveling bolts